WASTE WATER BLADDER SURGE VESSEL

- Internal Bladder seperating the Liquid and Air

- Used for Raw and Waste water applications with solids and sediments

- Available only in Vertical orientation (150L to 70,000L)

- No Permanent regulation system required

- No Electricity required to operate the surge vessel

- Specially reinforced designed bladder to protect against aggressive fluid environments

- Design pressures up to 40 bar

- Green Energy Solution – Virtually maintenance free and a more reliable hydro-pneumatic solution

For more information including vessel Operation, Installation & Maintenance manual please contact us on info@safesurge.com.au

WASTE WATER BLADDER VESSELS

A bladder surge vessel or bladder surge tank has the same mission with regard to surge control as the traditional compressor vessel.

The objective of this pneumatic solution is to simplify the method of regulation. In a similar way to a vessel controlled by compressors, a pre-charge pressure is calculated to give the required elasticity to push the water into the system following a pump shut down or power cut.

The major difference being that the Air is contained within a rubber bladder. Therefore, as there is no contact between the compressed air and the water there is no dissolution. There is thus no requirement for a permanent regulation system including compressors, complicated control systems and extensive maintenance. If the Bladder vessel is fitted with the correct level monitoring equipment, then it is virtually maintenance free.

Once the vessel has been commissioned and the correct precharge has been introduced, the vessel will operate automatically emptying when called upon and refilling with the return waves until naturally refinding its steady state balance.

Charlatte have been successfully manufacturing bladder vessels from 50L to 70,000L.

CONCEPTION OF A EUV BLADDER VESSEL FOR WASTE WATER

This type of vessel is vertical. It is manufactured from carbon steel containing a specially manufactured Butyl bladder coated with with a proven protective coating which is highly resistance to aggressive waste water. All vessels come with flanged connections to connect straight onto the pipework and is equipped with an anti-extrusion grill.

The vessels are treated internally with a highly resistant Epoxy paint as corrosion protection and externally coated to client specification.

In order to verify the level in the vessel it can be equipped with a differential pressure transmitter which offers 24 hour monitoring and is connected back to the PLC/SCADA control system. The vessels are also equipped with pressure gauges to verify the initial precharge pressure.

WASTE WATER BLADDER VESSEL OPERATION

ARAA DIPPING TUBE SURGE VESSEL

- This vessel design contains no Bladder. It has a specially design dipping tube and float valve custom made to meet the requirements sized in the hydraulic model analysis

- Used for waste water applications with solids and sediments

- Available only in vertical orientation (500L to 70,000L)

- Mainly used for long flat pipelines with low head pressure

- Specially designed and manufactured for project specific parameters – i.e. width of dipping tube, length of dipping tube etc

- Green Energy Solution – completely pneumatic and do not require electricity or air compressor to operate

For more information including vessel Operation, Installation & Maintenance manual please contact us on info@safesurge.com.au

ARAA DIPPING TUBE VESSELS

This type of vessel is commonly designed and used for flat profile pipelines.

As hydraulic engineers know the volume of a surge tank increases as the geometric head decreases (for the same length and discharge). This is due to the fact that we are dealing with energy : potential gravity energy does not exist in flat profiles where the flow never stops, and elastic energy is smaller in the vessel when the gas is less compressed.

When it is possible a good solution is to use external atmospheric energy and feed the system with atmospheric air, using limitless amounts of free energy. This job is perfectly achieved by the ARAA Dipping Tube Vessel.

As these flat profiles are frequent in sewage systems, the design of the device is adapted to raw water and effluents. They have been successfully used for over 20 years from 50L to 70,000L.

CONCEPTION OF THE ARAA DIPPING TUBE VESSEL

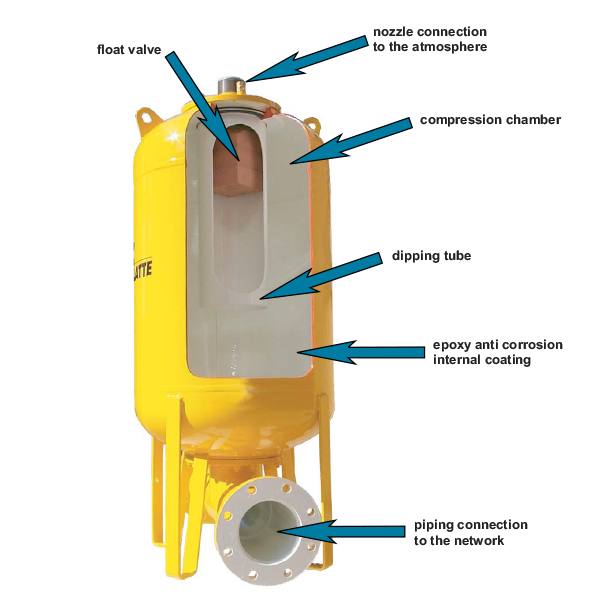

This type of vessel is vertical and connected to the pipework by a large connection pipe at the bottom. The top of this vessel has a compression chamber limited by the dipping tube or ventilation tube with a shut off float valve.

This special Charlatte Reservoirs patented vessel has three different operations:

- Compressed air vessel as the compression chamber traps air.

- Chimney when the float is open in the dipping tube.

- Air valve if all the water volume has been delivered to the pipework

As there is no bladder in the vessel, the connection pipe is completely open and there is absolutely no risk of obstruction if used in a sewage system.

With this type of surge vessel, a pump shut down once a day is required to replenish the air in the compression chamber.